How Lumber Grading Works

Lumber comes in all shapes, sizes and qualities. When you're selecting wood for a home constructions project, the lumber grading system will help you differentiate between the different woods and guide you in your selection. Learn about lumber grades below. That way, when you hire a carpenter, you'll already be informed and able to discuss which wood is best for your project.

Softwood vs Hardwood

Softwood lumber in the United States is most commonly graded according to the guidelines of the American Softwood Lumber Standard PS 20-70, established by the US Department of Commerce. In this article, you will learn about the grading system for softwoods, the most common type of wood used for construction.

Hardwoods are graded differently. Most of the hardwood lumber in the United States and Canada is graded following the rules established by the National Hardwood Lumber Association (NHLA). For more information on hardwood lumber grades, including a helpful chart, visit woodbin.com.

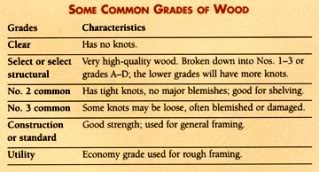

A General Guide to Basic Lumber Grades

The two main classifications of lumber are select lumber and common lumber. Select lumber (also known as factory select or select shop) is considered the finest and best for use in finishing projects, while common lumber is best for general building and construction.

- Select Lumber Classifications:

Natural finishes are graded either A or B.

Grade A is nearly free of defects and blemishes.

Grade B contains a few minor blemishes.

Painted finishes are graded either C or D.

Grade C contains more significant blemishes, and more of them, than woods in Grade B.

Grade D has even more blemishes than Grade C. Either grade, C or D, presents a satisfactory appearance when painted.

- Common Lumber Classifications:

No. 1 (construction use) is sound, strong, tight-knotted stock, with straight grain, containing only a few minor defects. No. 1 has no knotholes or other serious defects. It must be suitable for use as grain-tight lumber. Used for siding, cornices, shelving, paneling, some furniture.

No. 2 (standard use) grade has more and larger knots and blemishes than No. 1. Relatively strong; to be used where appearance is unimportant.

No. 3 (utility use) contains a few defects, larger and coarser than those in No. 2; for example, occasional knotholes. Does not take paint well. Used for crates, sheathing, sub-flooring, small furniture parts.

No. 4 (economy use) is low-quality material, which contains serious defects like knotholes, checks, shakes and decay.

No. 5 commonly holds together only under ordinary handling and where appearance is not important. This kind of wood is not paintable.

The first three grades are the ones you'll usually find in retail lumber yards; numbers 4 and 5 are generally for commercial applications only. Lumber grades are ink-stamped on the wood.

Updated February 4, 2018.

Looking for a Pro? Call us (866) 441-6648

Carpentry Average Costs

Carpenters Experiences

The Stamped Concrete Patio I’ve Been Waiting For

Deck Repair On A Deadline